1. Understand the working environment: Before selecting an electric valve model, you first need to have a detailed understanding of the working environment. This includes factors such as temperature, humidity, corrosiveness, and pressure level. Different working environments have different requirements for the material, sealing performance, and corrosion resistance of electric valves. For example, in a humid or corrosive environment, it is necessary to select a material with good corrosion resistance to ensure the long-term stable operation of the electric valve.

2. Determine the characteristics of the fluid medium: The characteristics of the fluid medium are an important consideration in selecting an electric valve model. The properties of the medium, such as corrosiveness, viscosity, temperature, pressure, etc., will directly affect the material selection, sealing method, and valve type of the valve. For example, for corrosive media, it is necessary to select a material with good corrosion resistance and take appropriate sealing measures to prevent medium leakage.

3. Clarify the functional requirements of the valve: When selecting an electric valve model, it is necessary to clarify the functional requirements of the valve. This includes whether flow control is required, the accuracy of flow regulation, and the switching speed. For occasions where precise flow control is required, an electric valve with high-precision adjustment function should be selected; for occasions where fast switching is required, an electric valve with a faster switching speed should be selected.

4. Choose the right valve type:

Depending on the usage scenario, different types of electric valves can be selected. The electric unit electric valve has a simple structure and is cheap, suitable for small on-off flow; the electric servo electric valve has a high-precision adjustment function and is suitable for occasions that require automatic adjustment and accurate positioning; the electric angle travel electric valve is suitable for occasions with a large rotation angle; the electric rotary electric valve is suitable for occasions that require frequent rotation.

5. Consider the performance parameters of the electric device:

The performance parameters of the electric device are important factors to consider when selecting the electric valve model. This includes the rated output torque, rated output speed, protection level, etc. The rated output torque needs to be selected according to the valve size and the required torque to ensure that the valve can open and close normally. The rated output speed determines the switching speed of the valve. In addition, the protection level is also very important, and the corresponding protection level needs to be selected according to the harshness of the working environment.

6. Consider additional functions and special requirements:

When selecting the electric valve model, it is also necessary to consider whether there are additional functions and special requirements. For example, some occasions require on-site buttons to facilitate on-site operation; some require 4-20mA signal output to connect to the control system; and some special occasions may require a manual reduction box to achieve manual operation. In addition, it is also necessary to consider whether there are special safety requirements, such as explosion-proof and flameproof.

7. Brand and price considerations:

When choosing an electric valve model, brand and price are also factors to consider. Choosing a well-known brand can ensure the reliability of product quality and after-sales service. At the same time, on the premise of meeting the needs, price factors must also be considered to choose products with high cost performance. However, it should be noted that price is not the only criterion, and other factors such as performance, quality, and service must be considered comprehensively.

8. Check specifications and certifications:

When choosing an electric valve model, it is necessary to carefully check the specifications and certifications. The specifications include the size, material, flow characteristics, etc. of the valve, and it is necessary to ensure that these parameters meet the actual needs. At the same time, it is also necessary to check whether the product has obtained CE, explosion-proof and other certifications to ensure product quality and safety. These certifications are an important basis for evaluating product quality and safety.

9. Consider installation and maintenance: When choosing an electric valve model, you also need to consider the convenience of installation and maintenance. First, you need to consider the installation space, connection method, and compatibility with other equipment of the electric valve. Make sure that the selected model can be easily installed into the existing system. Secondly, you need to consider the maintenance requirements of the electric valve. Choosing an electric valve that is easy to maintain and repair can reduce maintenance costs and downtime. In addition, you also need to consider the after-sales service and technical support provided by the supplier to ensure that you can get timely help and support during use.

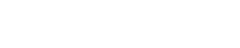

Dy-7010 Corrosion Resistant Small Brass Electric Solenoid Valve 220V

Flexible application, quiet operation, constant torque

Manual control during system debugging and maintenance

It takes up little external space during installation and can be installed close to the wall

Corrosion resistance, long life, small size

English

English 中文简体

中文简体

.jpg)

+0086-18067425071(Wechat)

+0086-18067425071(Wechat) +0086-574-62803230

+0086-574-62803230 Duoye0413@outlook.com

Duoye0413@outlook.com