In today's fast-paced industrial landscape, efficiency is a critical factor for success. As industries strive to optimize their operations, finding innovative solutions to improve productivity and streamline processes becomes paramount. One such solution that has gained significant attention is the electric ball valve. With its advanced features and automation capabilities, electric ball valves have emerged as a game-changer in enhancing efficiency across various industrial sectors.

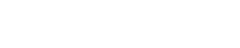

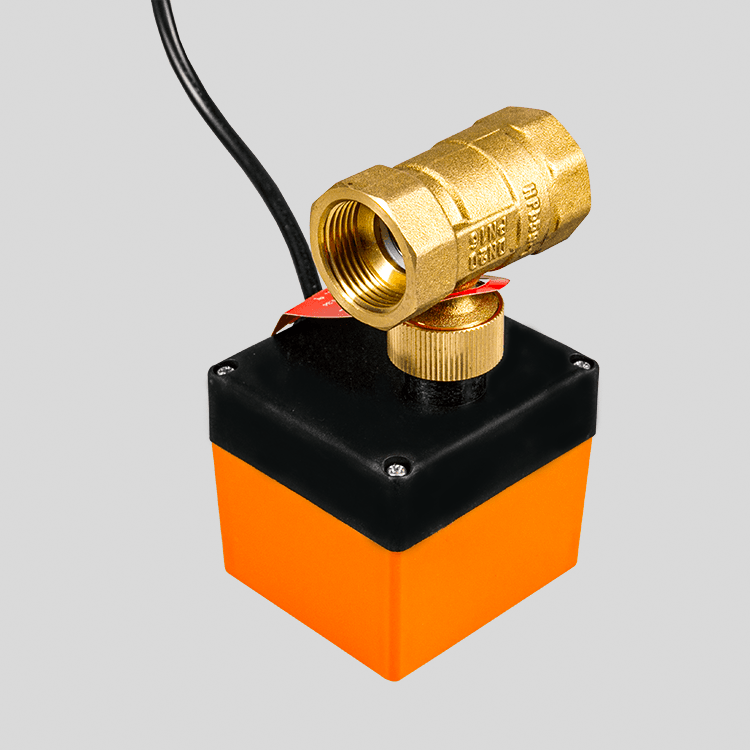

Electric ball valves are designed to control the flow of fluids, gases, and semi-solids in pipelines and industrial systems. Unlike their manual counterparts, electric ball valves utilize an electric actuator to open or close the valve, offering precise and automated control. This automation eliminates the need for manual intervention, reducing the potential for human error and enhancing overall process efficiency.

One of the key advantages of electric ball valves is their quick response time. Traditional valves may require several turns to open or close fully, whereas electric ball valves can actuate swiftly, minimizing downtime and improving the speed of operations. This rapid response time is particularly crucial in critical processes where timely control is essential.

Moreover, electric ball valves provide accurate flow control. The electric actuator ensures precise positioning of the valve, allowing for fine-tuning of flow rates. This level of control not only enhances efficiency but also optimizes resource consumption. Industries can achieve better utilization of resources, leading to cost savings and improved sustainability.

Another significant advantage of electric ball valves is their ability to integrate seamlessly into industrial automation systems. These valves can be easily incorporated into supervisory control and data acquisition (SCADA) systems, programmable logic controllers (PLCs), and other industrial control systems. This integration enables centralized monitoring and control of valves, providing real-time data on flow rates, pressure, and other critical parameters. Operators can remotely monitor and adjust valve settings, enabling efficient process management and troubleshooting.

Furthermore, electric ball valves offer exceptional reliability and durability. With no manual operation required, the risk of wear and tear is significantly reduced. Electric actuators are designed to withstand harsh industrial environments, ensuring long-term performance and minimal maintenance requirements. This reliability translates into increased uptime, minimizing disruptions and maximizing productivity.

Industries such as oil and gas, chemical processing, water treatment, and manufacturing have embraced electric ball valves for their efficiency-boosting capabilities. These valves find applications in various processes, including fluid control, mixing, blending, and diverting flows. Whether it's regulating the flow of chemicals, managing cooling systems, or automating batch processes, electric ball valves provide a versatile solution that can be tailored to specific industrial requirements.

In conclusion, electric ball valves have revolutionized industrial processes by significantly improving efficiency. With their automation capabilities, rapid response time, precise flow control, seamless integration, and robust reliability, these valves streamline operations and enhance productivity across diverse sectors. As industries continue to prioritize efficiency, the adoption of electric ball valves is poised to grow, driving the transformation of industrial processes into streamlined, high-performing systems.

Motor Type: Synchronous Motor Nominal

Driver torque: 3N_M/4N.M/8N.M

Pressure: PN16

Connection method: Pipe thread G Power

Power cord length: 300mm

consumption: 6W (only when the valve is open)

Medium temperature: 15~95℃

Close differential pressure: <0.4Mpa

Action time: 15 seconds, 30 seconds

Applicable medium: cold, hot water or 50% ethanol solution

Electrical Specifications: (50/60Hz) 24VAC/110VAC/220VAC

English

English 中文简体

中文简体

.jpg?imageView2/2/format/jp2)

+0086-18067425071(Wechat)

+0086-18067425071(Wechat) +0086-574-62803230

+0086-574-62803230